Applied Structural Drying

Dry Force Water Restoration's Applied Structural Drying

Case Study | Southlake, TexasApplied Structural Drying

A case study in the value-added/saved from the utilization of a team of highly-trained restoration specialists.Water Damage is a progressive and time-sensitive form of disaster. As such, Dry Force strives to begin water mitigation as soon as possible.

From the moment a customer provides an initial report of loss, Dry Force's team of water mitigation and restoration specialists are dispatched to the residence. Upon arrival, these highly-trained and professional specialists inspect the damage, and begin preparing a drying plan. Soon after, the emergency mitigation process is completed, and emergency drying procedures come into play.

Utilizing a combination of environmental controls, direct air flow, and speciality equipment, our team of specialist are prepared to respond within the hour, around the clock.

Background

These Materials Included:

- Cabinetry

- Plywood Subfloor

- Sand On-site Wood Flooring

- Ceiling and Wall Assemblies

- Drywall

- Multi-layered Base Trim

- MDF Crown Molding

- Framing Members (i.e. SPF 2x4s)

Day 1 Timeline

September 21, 2020- 6:37 PM: Initial report of loss

- 7:15 PM: Specialists are en route to the residence

- 8:01 PM: Initial inspection is completed; Drying Plan is built

- 10:19 PM: Emergency Mitigation has been completed

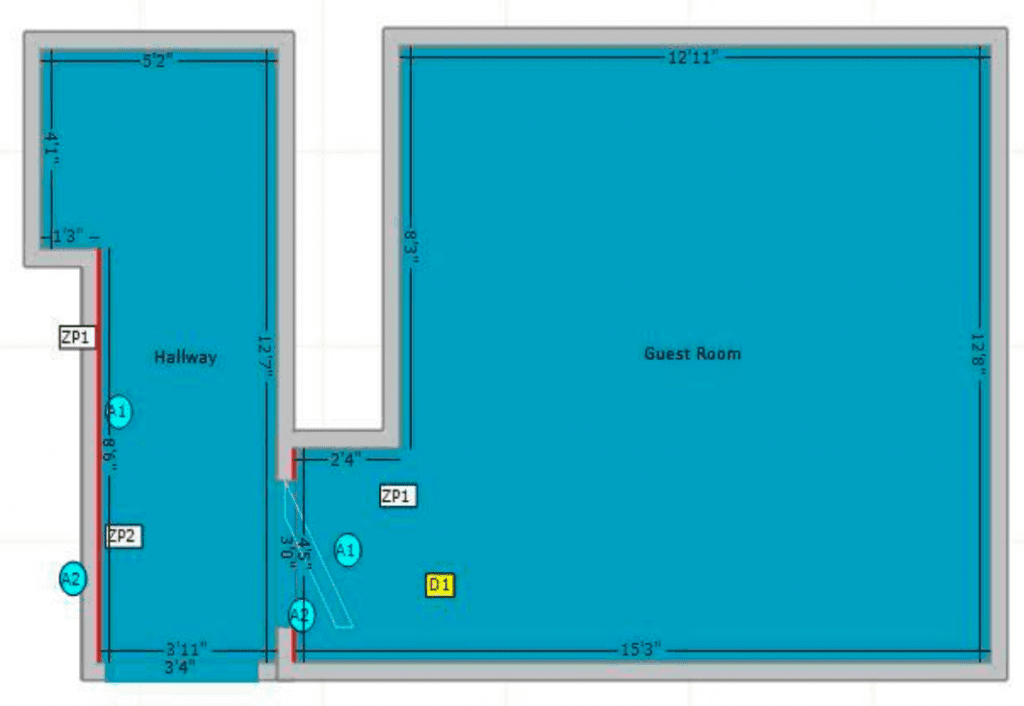

Emergency Drying Setup

Select a tile to learn moreEnvironmental Controls

Direct Airflow

Specialty Equipment

Environmental Controls

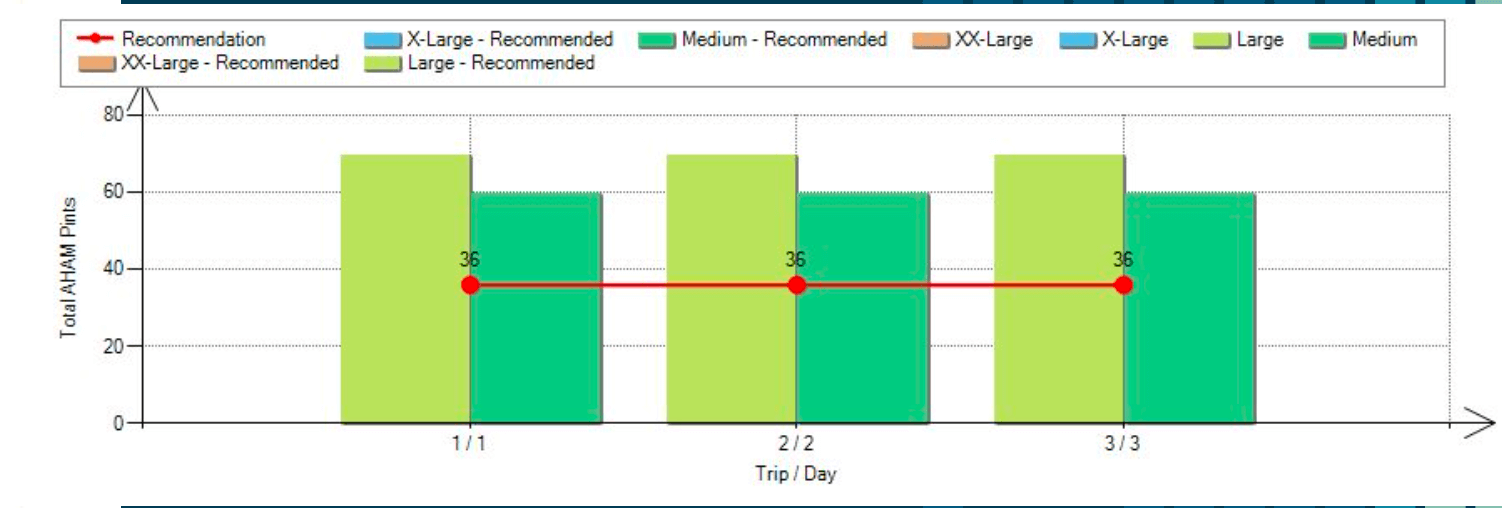

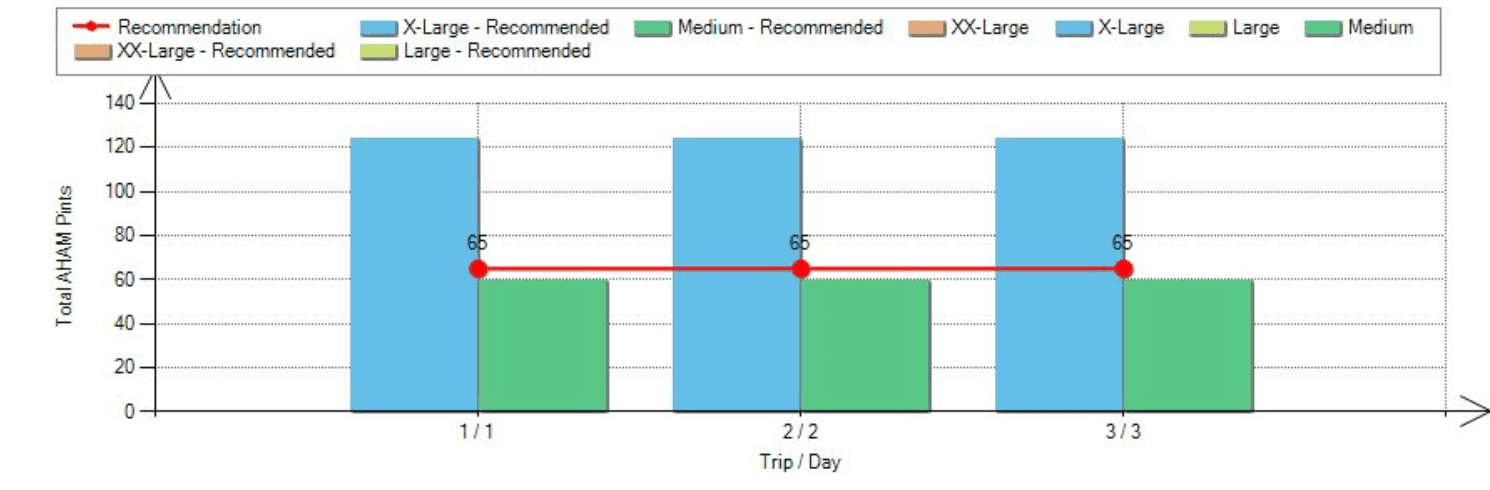

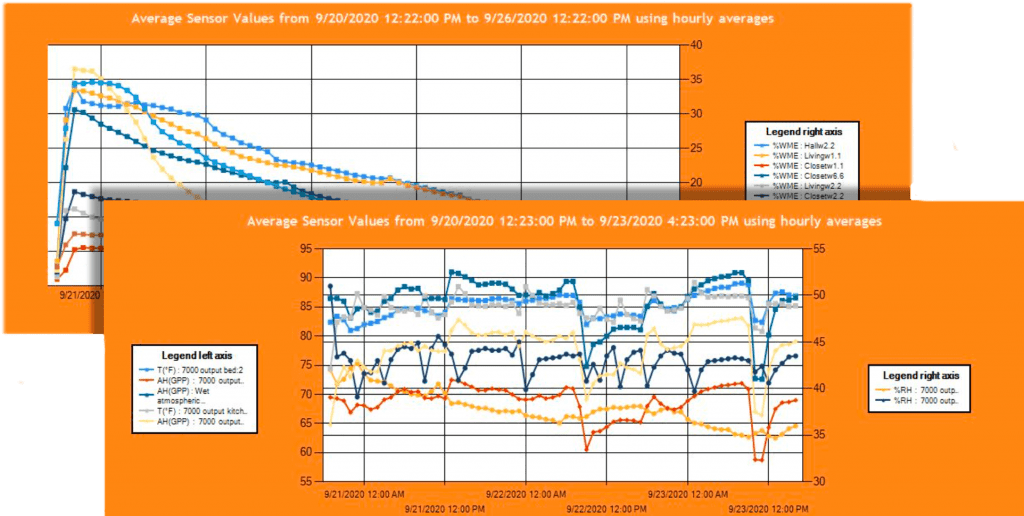

- Using Industry-specific software our specialist calculates the exact amount of dehumidification for the given loss.

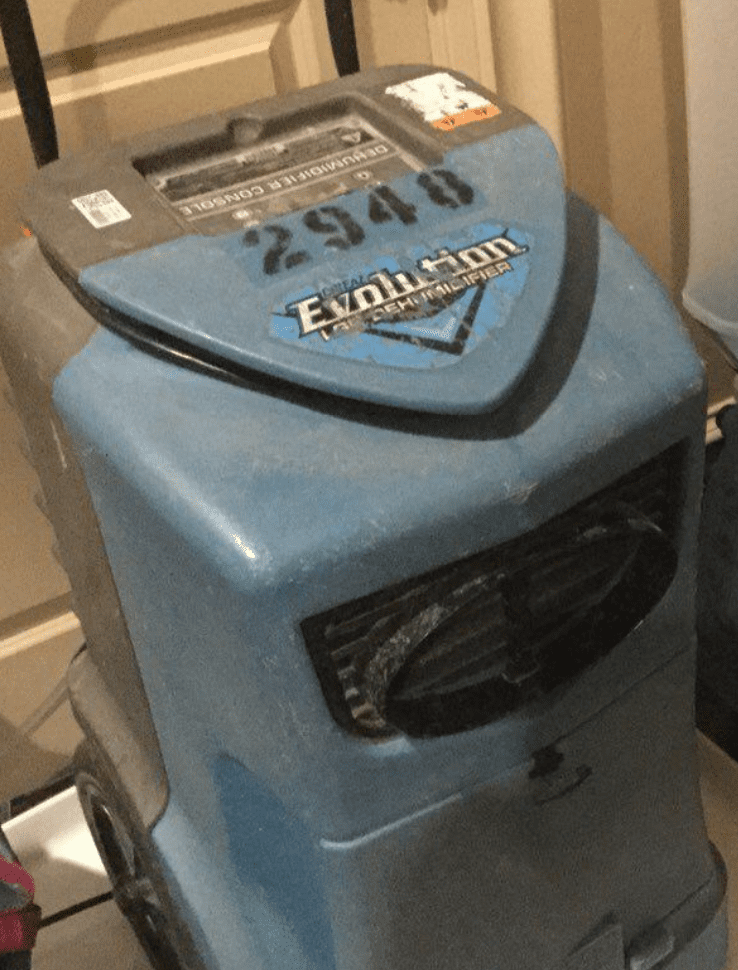

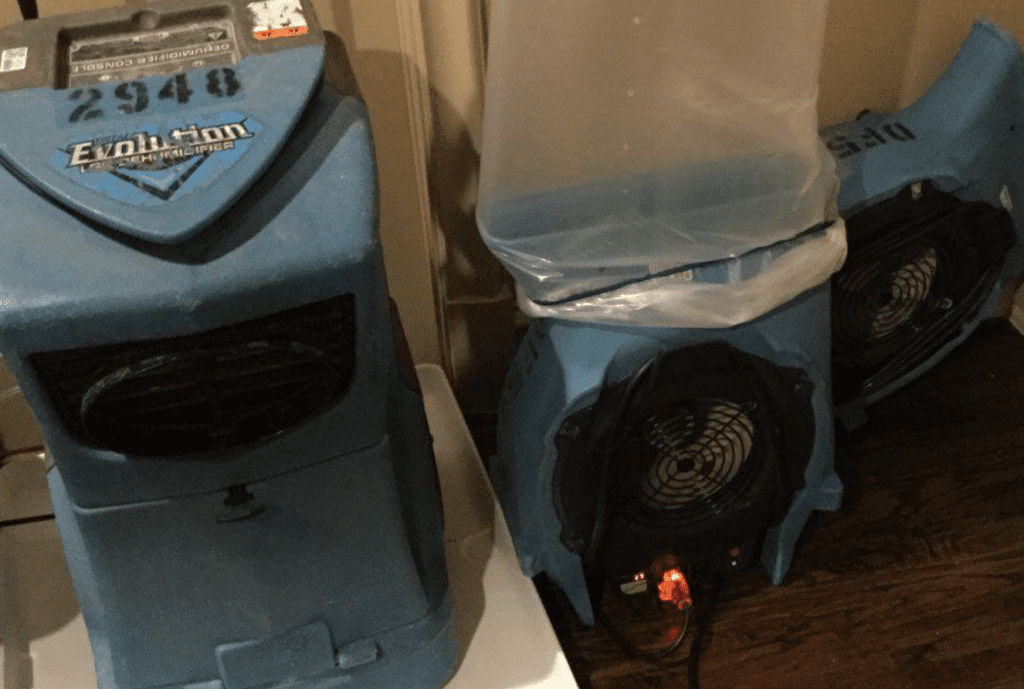

- Dehumidification: the removal of moisture from the air is accomplished with the most efficient low-moisture dehumidifiers on the market.

Direct Airflow

- Usage of Industrial High CFM Air Movers promotes the drying of materials.

- This drying can even be done through multi-layered materials when completed in conjunction with correct environmental controls.

- To ensure that even materials at great height get adequate airflow temporary ducting will be utilized.

Specialty Equipment

- Wood Floors offer a unique scenario where moisture will become trapped between materials that will not allow airflow or evaporation.

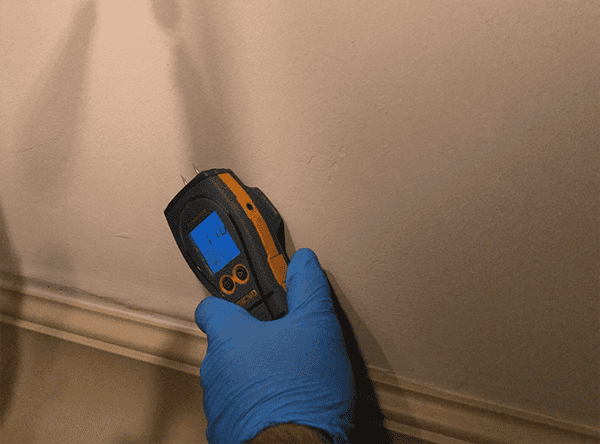

- Usage of non-destructive moisture detection equipment is often the only way to find such damage before physical deformity has occurred.

- When this occurs specialized training, techniques, and equipment must be utilized to force drying before irreversible damage has the ability to happen.

Ongoing Tracking/Monitoring

- Before equipment is ever removed from the materials, moisture levels are measured and documented by a specialist on-site using various Moisture Detection equipment and Methodologies.

Invasive Probing for Trapped Moisture

- Before equipment is ever removed from the materials, moisture levels are measured and documented by a specialist on-site using various Moisture Detection equipment and Methodologies.

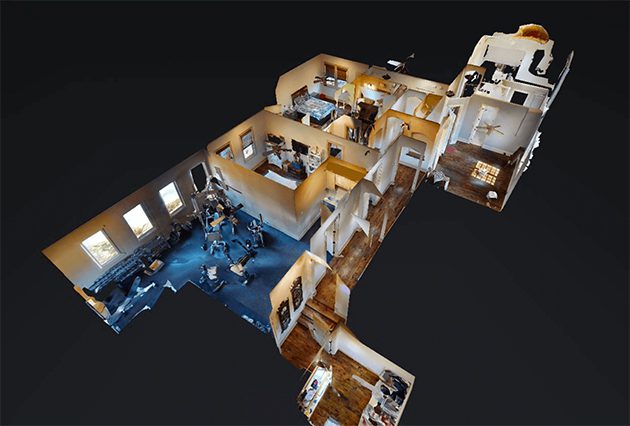

3-D Modeling: Matterport

Build Back

See how a restoration project advances from start to finish: