Applied Structural Drying

Dry Force Water Restoration's Applied Structural Drying

Case Study | Southlake, Texas Call For A Free Evaluation

Applied Structural Drying

A case study in the value-added/saved from the utilization of a team of highly-trained restoration specialists.Water Damage is a progressive and time-sensitive form of disaster. As such, Dry Force strives to begin water mitigation as soon as possible.

From the moment a customer provides an initial report of loss, Dry Force's team of water mitigation and restoration specialists are dispatched to the residence. Upon arrival, these highly-trained and professional specialists inspect the damage, and begin preparing a drying plan. Soon after, the emergency mitigation process is completed, and emergency drying procedures come into play.

Utilizing a combination of environmental controls, direct air flow, and speciality equipment, our team of specialist are prepared to respond within the hour, around the clock.

Background

During a routine plumbing test, there was an unknown blockage of a 2nd-floor sink drain. This blockage caused water to overflow, and affect materials on the 2nd and 1st floors.

These Materials Included:

- Cabinetry

- Plywood Subfloor

- Sand On-site Wood Flooring

- Ceiling and Wall Assemblies

- Drywall

- Multi-layered Base Trim

- MDF Crown Molding

- Framing Members (i.e. SPF 2x4s)

Day 1 Timeline

September 21, 2020- 6:37 PM: Initial report of loss

- 7:15 PM: Specialists are en route to the residence

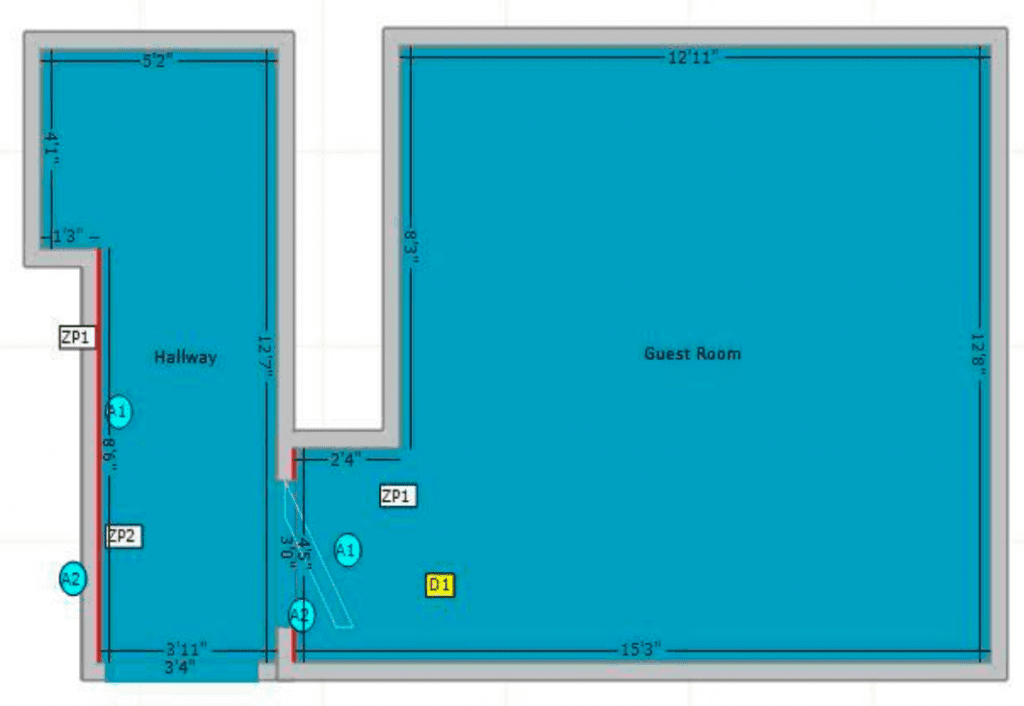

- 8:01 PM: Initial inspection is completed; Drying Plan is built

- 10:19 PM: Emergency Mitigation has been completed

Emergency Drying Setup

Select a tile to learn moreEnvironmental Controls

Control of the drying environment is critical to

creating the “Thirst” required to force moisture from a semi-porous material (i.e. Drywall/Wood/Concrete).

Direct Airflow

Once moisture has been brought to the surface of

any given material on going high CFM (Cubic Foot per Minute) air flow is required to force that moisture away. Without this Drying would slow to the point that Microbial Growth is possible.

Specialty Equipment

When moisture is trapped within an assembly that

will not allow the moisture to exit with typical drying methods, specialized equipment is utilized to force drying to occur.

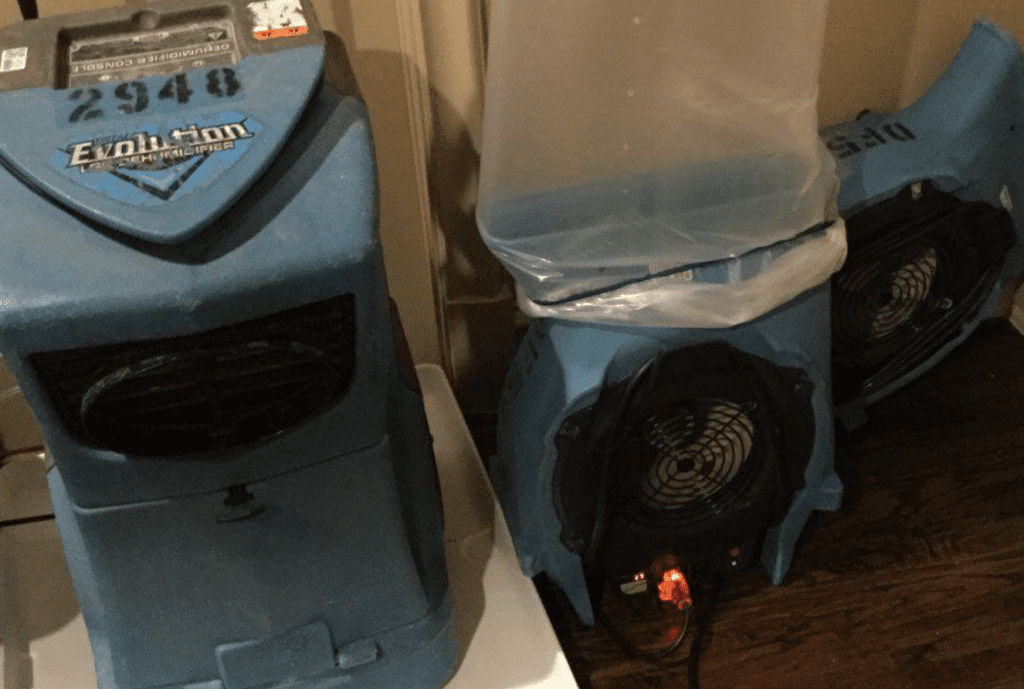

Environmental Controls

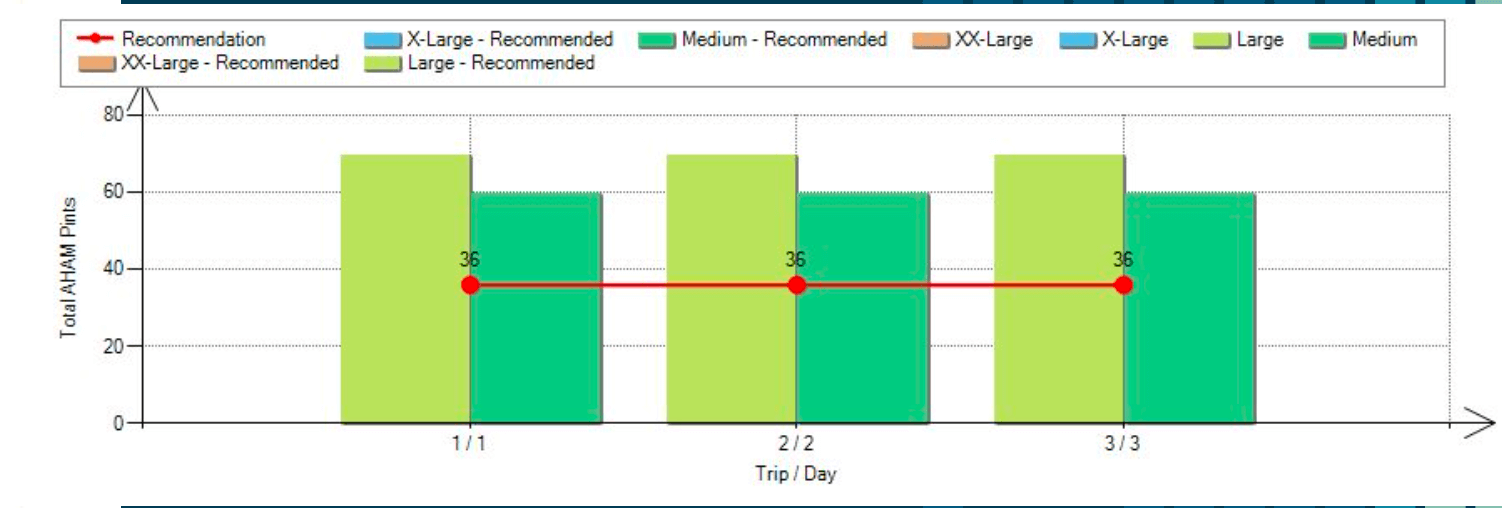

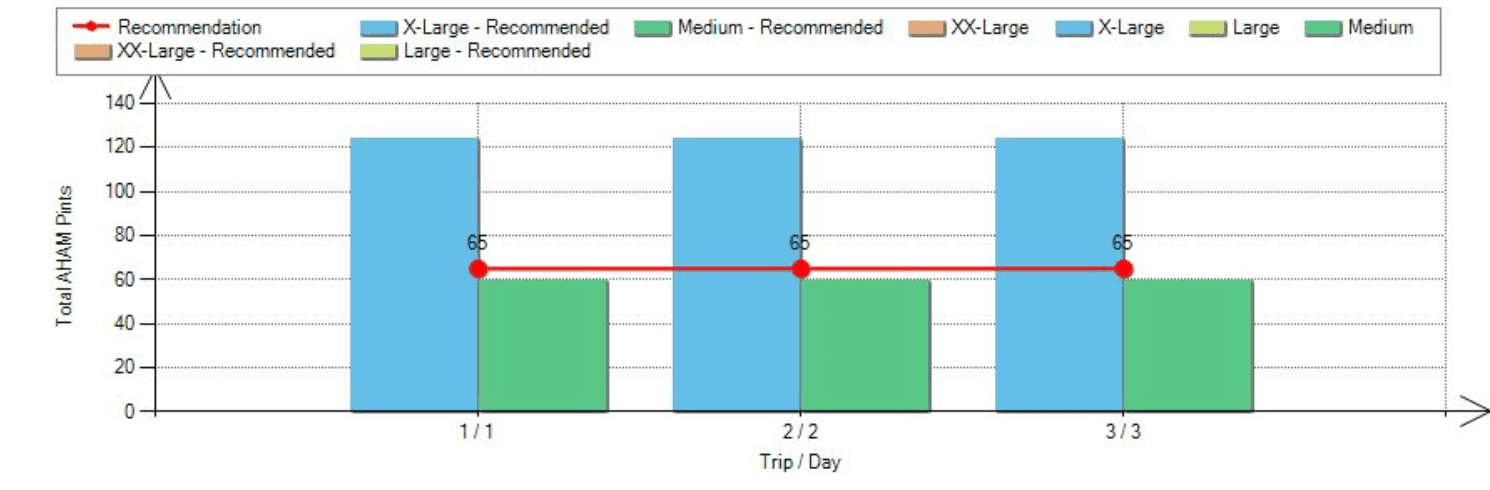

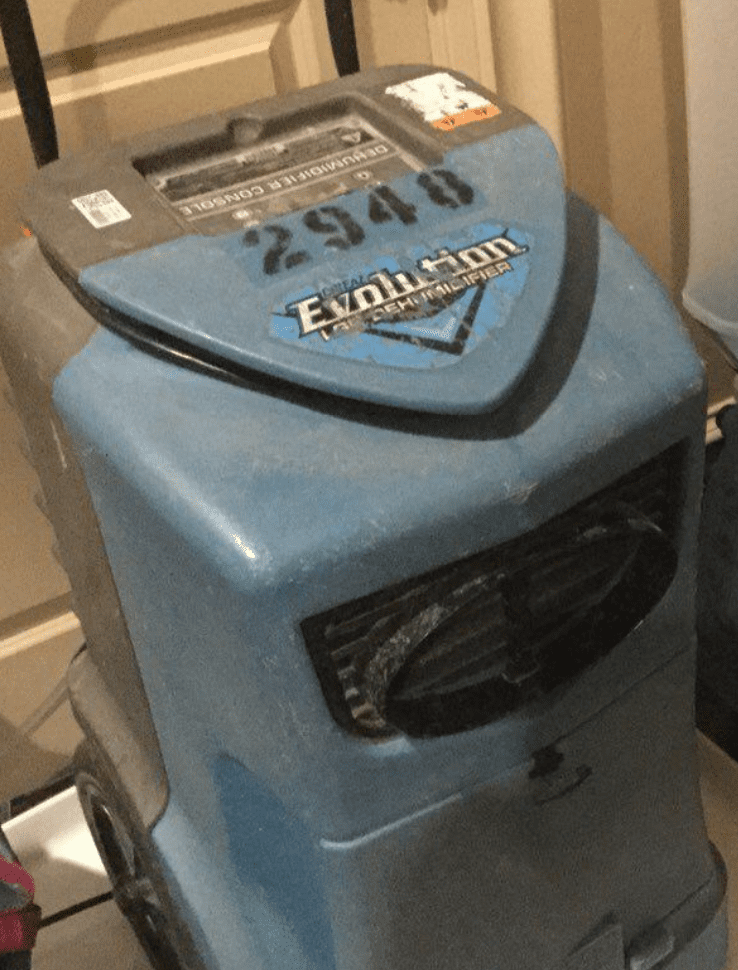

- Using Industry-specific software our specialist calculates the exact amount of dehumidification for the given loss.

- Dehumidification: the removal of moisture from the air is accomplished with the most efficient low-moisture dehumidifiers on the market.

Direct Airflow

- Usage of Industrial High CFM Air Movers promotes the drying of materials.

- This drying can even be done through multi-layered materials when completed in conjunction with correct environmental controls.

- To ensure that even materials at great height get adequate airflow temporary ducting will be utilized.

Specialty Equipment

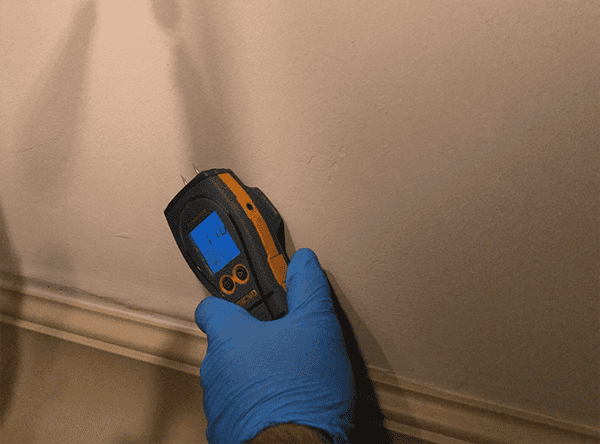

- Wood Floors offer a unique scenario where moisture will become trapped between materials that will not allow airflow or evaporation.

- Usage of non-destructive moisture detection equipment is often the only way to find such damage before physical deformity has occurred.

- When this occurs specialized training, techniques, and equipment must be utilized to force drying before irreversible damage has the ability to happen.

Ongoing Tracking/Monitoring

- Before equipment is ever removed from the materials, moisture levels are measured and documented by a specialist on-site using various Moisture Detection equipment and Methodologies.

Invasive Probing for Trapped Moisture

- Before equipment is ever removed from the materials, moisture levels are measured and documented by a specialist on-site using various Moisture Detection equipment and Methodologies.

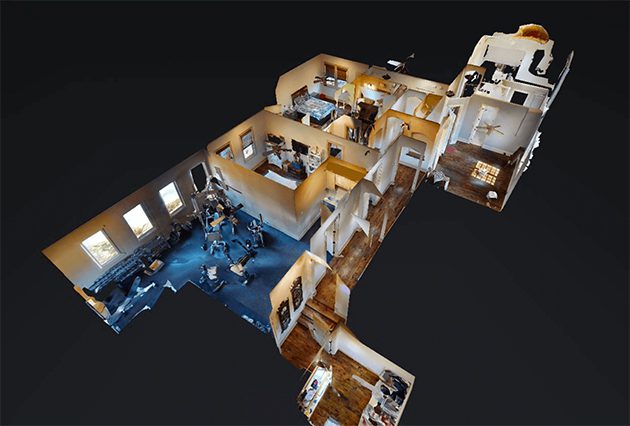

3-D Modeling: Matterport